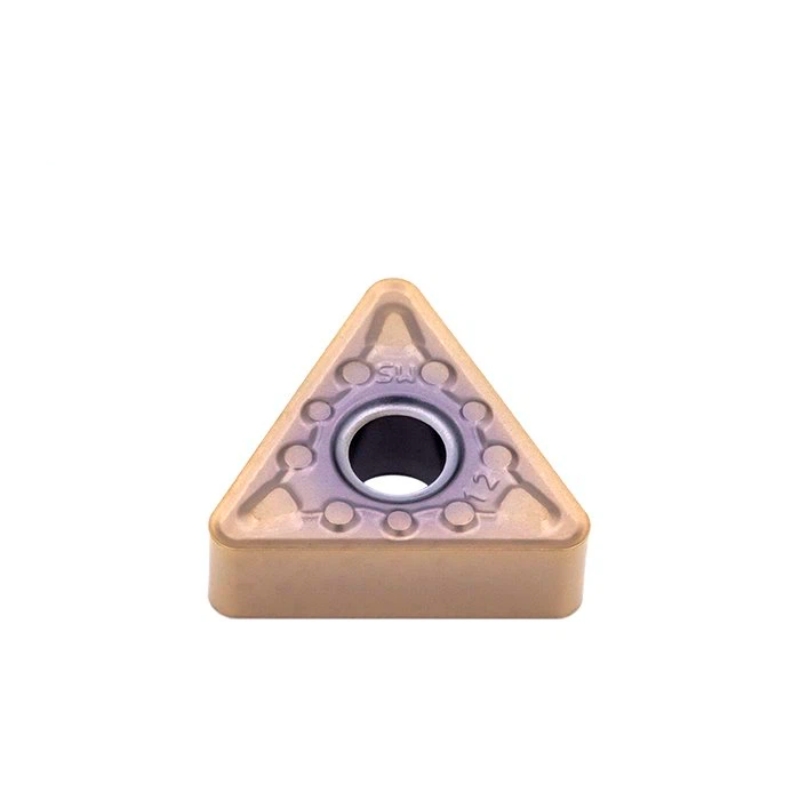

| Type | Grade | ||||||||||

| CVD | PVD | ||||||||||

| VK3020 | VK3040 | VK1025 | VK1325 | VK1525 | VK1328 | VR1010 | VR1520 | VR1525 | VR1028 | VR1330 | |

| VBET160404-DM | • | ||||||||||

| Length | Size(mm) | |||

| IC | S | d | r | |

| 16.5 | 9.525 | 4.76 | 4.4 | 0.4 |

1.What is insert cutting tool? Cutting tool inserts are replaceable attachments for cutting tools that typically contain the actual cutting edge. Cutting tool inserts applications include: boring. construction. 2.What is insert grade? An insert's material, or grade, is designed to suit a particular machining application, and even though two inserts may look the same, the base material and the coating (if there's one) can be very different 3.What are types of milling? Shoulder milling. Face milling. Profile milling. Groove milling and parting off. Chamfer milling. Turn milling. Gear machining. Holes and cavities/ pocketing. 4.What is the delivery time of your products? It depends on the inventory availability. If the items are in stock, the processing time would be within 24 hours; but if not, the Processing time would be around 20-30 working days. Hot Tags: cemented carbide inserts, China, suppliers, factory, buy, price, cheap, quotation, free sample

1.What is insert cutting tool? Cutting tool inserts are replaceable attachments for cutting tools that typically contain the actual cutting edge. Cutting tool inserts applications include: boring. construction. 2.What is insert grade? An insert's material, or grade, is designed to suit a particular machining application, and even though two inserts may look the same, the base material and the coating (if there's one) can be very different 3.What are types of milling? Shoulder milling. Face milling. Profile milling. Groove milling and parting off. Chamfer milling. Turn milling. Gear machining. Holes and cavities/ pocketing. 4.What is the delivery time of your products? It depends on the inventory availability. If the items are in stock, the processing time would be within 24 hours; but if not, the Processing time would be around 20-30 working days. Hot Tags: cemented carbide inserts, China, suppliers, factory, buy, price, cheap, quotation, free sample